A Quick Change Tool Post

Here's a random collection of pics. I appreciate that there's almost no detail here.E-Mail me if you'd like to know more.

A quick change toolpost is a bit of a luxury item for a manual lathe. Sure, it gets every tool on centre, but buying a holder for each and every tool you own is expensive, making them is a bit of a pain..

On a CNC machine though, a QTP allows you to program the length and offset of each tool and then write code that machines using one tool, prompts for the next tool and continues without you having to re-set the X axis each time. I thought about it for about 2 seconds then hit EBay!

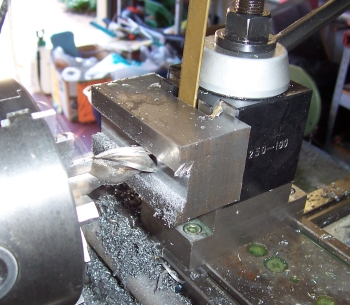

I picked this type of toolpost because the holders required the least amount of machining to make

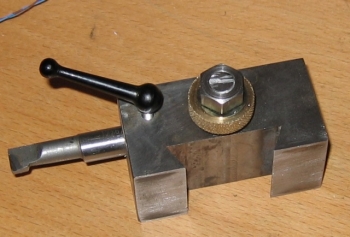

Having long ago ditched the Mickey Mouse compound slide and its flimsy clamping plate, I needed to lift the new toolpost up a bit so that the tools could be brought on center in about the middle of the adjustment range. A few chunks of mild steel and an M14 bolt later and we were in business

So far so good. Now I needed about 6 more toolholders, no point in half doing this job!

The local metal merchants aren't the cheapest. But they're more than happy to cut to length. Here are 6 blanks that have just been roughed out and are about to get a visit from a dovetail cutter. Many thanks to my mate (you guessed it) Dave for the use of his mill.

I actually cut too much away and had to pack it out, a bit dissapointing that. I ended up welding a strip in and taking a skim cut..

The next step was to slot them to take the tools. I use tools between 12 and 16mm so I cut the slots with an 18mm endmill.

I slotted 4 of them and kept two for spares.

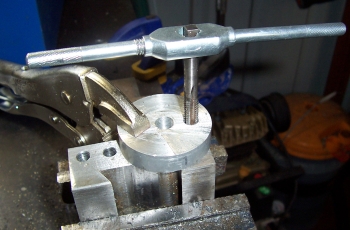

Finally I drilled and tapped the M8 and M10 holes for the clamping bolts and height setters.

The Al is just a bit of scrap with an 8mm hole in it to keep the tap straight

TADA!

Some special toolholders

A holder for the brazed tip tools from my boring head |

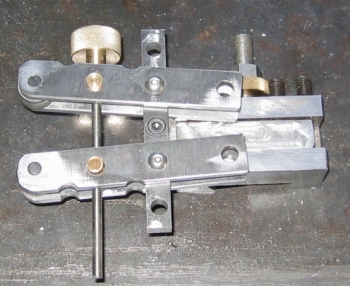

A holder for the most adjustable knurling tool you'll ever see. Since taking this photo I've removed the shank from this tool and just welded the vertical bar to a thinner blank with a dovetail in the back |

Not a great shot of it, but a small toolpost milling spindle |