Electronic Lead Screw

E-Mail me if you'd like to know more.

OK, I get a LOT of mail about this little circuit. I'll start by saying that this is a dead project. I only built it to prove a point. I did and now there are a bunch of people who:

a: Still refuse to admit they are wrong

b: Don't like me very much.

I do not consider this finished code. It works, but lacks a fair bit of finessing. The reason for this is that an ELS is a fundamentally flawed concept. Don't build this thing! Grab a PC and some shareware (TurboCNC,EMC or Mach3) software. It'll be faster better and easier. Additionally, You'll have a simple path to full CNC.

Here's one I prepared earlier

It runs a modified version of Turbo CNC to do the same job. Took me a day or two to get it together and it has since then cut a lot of threads...

But you're not going to listen. You've already rationalised your fear of the complexity

of CNC by saying something like "But I only need an ELS", you think that an ELS will mean you don't

have to worry about tuning motors, expensive drivers and ball screws.

You are wrong.

All of these issues remain, regardless of how you drive the machine, as soon as you get over the

initial intimidation, you are going to want a full CNC setup. Everyone does.

For a great example of the journey you are embarking on. Visit the ELS group on Yahoo

I said something a bit like this very early on (In a bit more of an abrasive tone) on that forum and got booted off.

Here's a link to a reference to that post.

But you aren't going to listen to me. You've convinced yourself that you know what you want better than I do. I've helped half a dozen people down this path. It always ends the same way. But what do I know. I'm just the dumb guy with the website you're looking at who's obviously done it all before.

OK end of rant

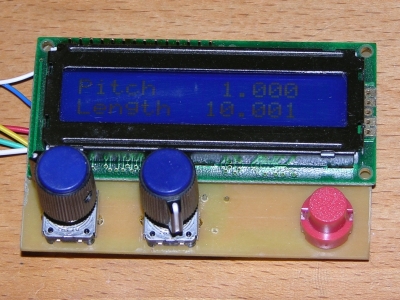

The circuit I built has two knobs (little rotary encoders) and one button.

You set the length of the thread by turning one knob.

You set the pitch of the thread by turning the other.

You push the button and it takes a pass, waits for you to wind the cross slide out.

You push the button and it moves the carriage back.

That's it.

So here is a link to the code

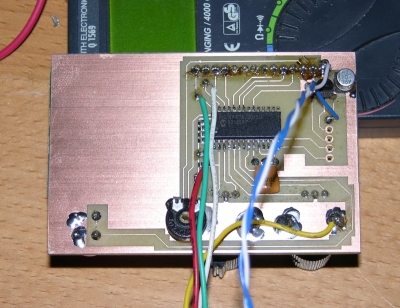

There's no schematic, pin connections are detailed in the code..