Speeds and feeds for various cutter material combinations

How fast to cut at what rpm in what material is a perenial problem for self taught machinists, Often we are guided by dogma, other peoples and our own, and never realise the full potential of the machines we use. Presented here are the results of some trials we did on a friends NC router I hope you find them useful in setting up your machine.Email me if you have any questions

Method

3 cutters in total were tried on 4 materials at 4 speeds. The spindle speed was kept at a fairly constant 20,000 (ish)RPM using the speed dial on this:

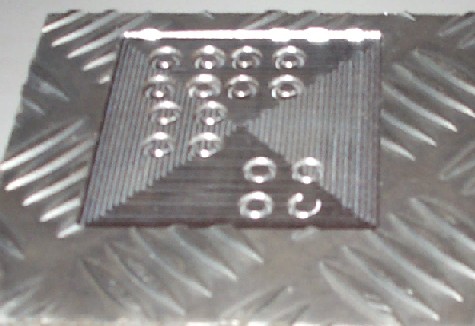

Each test consisted of cutting a small circle (12mm diam), helically interpolating down to a depth of 1mm then circularly interpolating to smooth the bottom off. These holes were machined in groups of 4, with each successive hole bing cut at double the feed rate of the previous. The cutters user were:

|

|

|

| 3mm single flute endmill | 2mm single flute endmill | 3mm single flute carbide router bit |

|---|

Grey PVC |

Acrylic (perspex) |

2000Series aluminium |

Aluminium chequer plate Aluminium chequer plate |

Results:

3mm Carbide Router

| 200mm/min | 400mm/min | 800mm/min | 1500mm/min | |

|---|---|---|---|---|

| PVC | Some Melting | Less melting | Good | Good |

| Acrylic | OK | OK | Good | Good |

| 2000Series | Good | Good | Good | Good |

| Chequerplate | Good | Good | Good | Good |

3mm Single Flute Endmill

| 200mm/min | 400mm/min | 800mm/min | 1500mm/min | |

|---|---|---|---|---|

| PVC | Some melting | Good | Good | Good |

| Acrylic | OK | Good | Good | Some light tooling marks |

| 2000Series | Good | Good | Good | Some light tooling marks |

| Chequerplate | Good | Good | Good | Some light tooling marks |

2mm Single Flute Endmill

| 200mm/min | 400mm/min | 800mm/min | 1500mm/min | |

|---|---|---|---|---|

| PVC | Good | Good | Good | Some light tooling marks |

| Acrylic | OK | Good | Good | Some light tooling marks |

| 2000Series | Good | Good | Good | Some light tooling marks |

| Chequerplate | Good | Good | Good | Broken bit |

Discussion

As a rule, the faster we cut the better it turned out. The light machining marks observed at the fastest cutting speeds were caused by the poor mounting of the workpieces (double sided tape). We repeated the tests with better clamps and they went away. The 2mm bit only just let go at the end of the cut, repeating the test with a 2.5mm cutter and we got a perfect result. In any case, I can't emphasise enough how crappy and tough that chequer plate is.